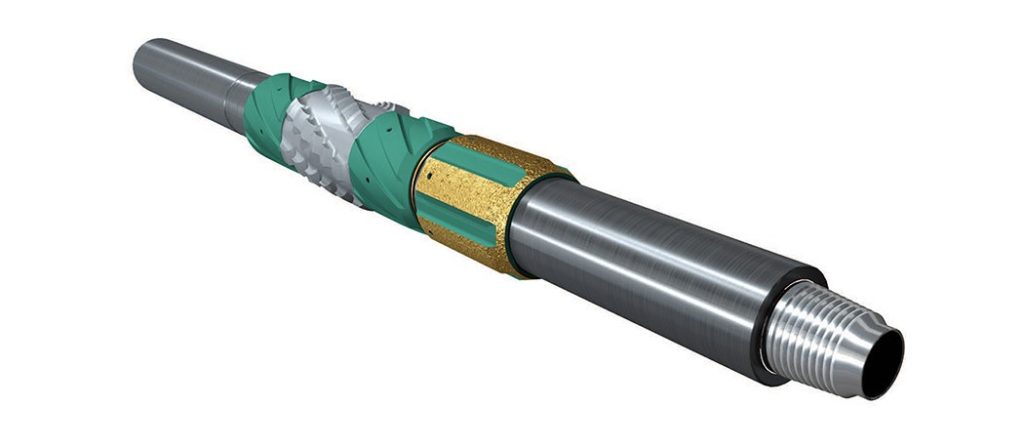

MunchRdillo™ Scraper Milling Tool is a robust 360° contact free-rotating wellbore clean-up tool that combines the function of a scraping element and a heavy duty mill on one tool mandrel, which can be run modularly as part of the ArmRdillo™ Wellbore Clean-Up System. The MunchRdillo™ can be adapted to suit any casing size and drill pipe combination.

Features

- Strong, self-sprung, single piece Scraper Broach machined from a single billet of steel with multiple rows of overlapping teeth

- Scraper Broach flexes to fit the casing ID, while being stiff enough to provide strong scraping force which ensures true 360° coverage where sprung pad scrapers cannot

- Tungsten carbide cement mill is attached to the tool mandrel to mill cement and other debris

- Two fluted Centralizer Rings provide centralization and protects the Scraper Broach

- Free rotating tool design with Internal Bearing Rings to prevent mandrel, tool or casing wear

- Can be quickly assembled redressed on location or support base with simple hand tools

- No external bolts, clamps or fasteners that can come loose down hole

- Robust assembly method with multiple back-ups

Benefits

Cost savings

- Combines the functionality of the RazRdillo™ Casing Scraper with the ruggedness of an aggressive fixed blade string mill

- Milling of cement and scraping can be performed in a single trip saving rig time

Integrity

- The ArmRdillo™ Wellbore Clean-Up System can be provided with any type of rig end connections including premium and high torque connections reducing the need for reduced strength crossovers

- Single piece mandrel with no internal connections for increased strength

Applications

- Drilling hardened cement, and other accessories inside the wellbore in a single trip

- Pre-completion wellbore clean-up operations to remove hardened cement sheath, scale, mud solids, cuttings and other detritus from the casing wall

- Extended reach wells where high strength drill pipe connections are required

- Remote locations where logistics are constrained and tool maintenance can be performed at the rig site

- Short tripping where multiple tools need to be run on the same string

Operational

- While running in hole, the teeth of the MunchRdillo™ Scraper Broach scrapes the casing wall removing cement sheath and other debris

- Cement plugs and accessories can be drilled inside the casing as required following standard cement drilling practices and parameters

- The MunchRdillo™ mill breaks up any large cement pieces or debris that is carried past the tool into smaller more manageable pieces

- The MunchRdillo™ is reamed across the drilled out cement depths to remove any residual cement sheath in a single trip saving valuable rig time