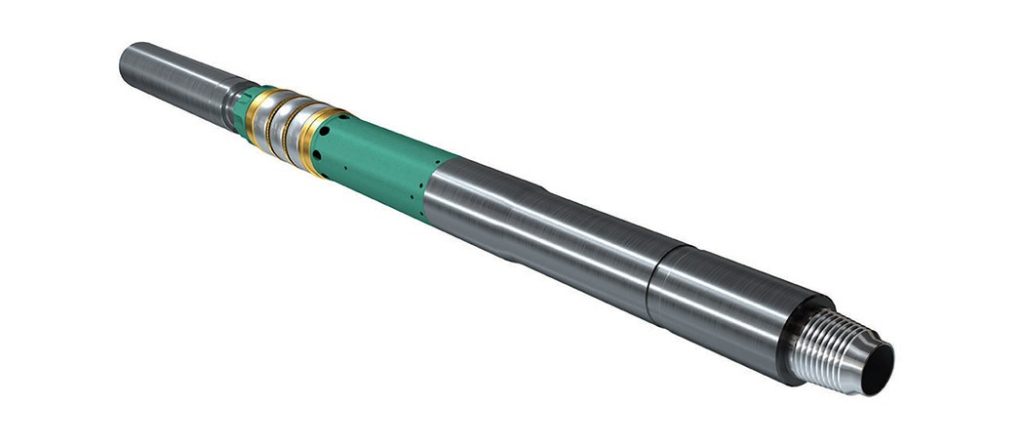

The DTectR™ Inflow Test Packer is a simple but effective well integrity testing device which performs a negative pressure test on a liner top. The design of the tool allows the test to be performed during wellbore cleaning operations, eliminating the need for a separate trip in hole.

Features

- Generous internal bypass allows prevents damage to the packing element whilst circulating at high rates required for wellbore cleaning

- Shear screws can be customized to suit requirements

- Set by string compression applied through the tool joints

- Compression spring returns tool to unset position after picking up

- Robust assembly method with back-ups

- Compatible with other OWS ArmRdillo™ wellbore clean-up tools

Benefits

- Cost savings

- The DTectR™ Inflow Test Packer saves the need for a separate trip in hole to inflow test the liner

- Integrity

- Tests the integrity of the liner in a safe manner before the well is displaced

- Reducing Non-Productive Time

- Discovering a leaking liner after the completion has been installed may result in a costly workover

Applications

- Pre-completion wellbore clean-ups for where negative testing of a liner is necessary

Operational

- The DTectR™ Inflow Test Packer can be run independently or as part of a comprehensive wellbore clean-up string

- The DTectR™ Inflow Test Packer is typically spaced out with a Liner Landing Sub or Top Dress Mill below it, which lands out inside the Liner TopPBR

- Whilst running in the hole, the string can be reciprocated and rotated to allow the scrapers and other tools to clean the critical depths

- The tool is set by applying compressive force which shears screws allowing the tool to stroke and set the packing element

- Picking up weight will relax the tool and unset the packing element

- When required to inflow test, pump predetermined volume of under-balancing fluid into the string and set the packer

- By bleeding the work string pressure the liner integrity is tested and any leaks will be identified

- After testing is complete the under-balancing fluid can either be reversed out, or pumped out as part of the displacement to continue the wellbore clean-up operation

- The OWS Weight Set Circulating Tool can also be run above the DTectR™ Inflow Test Packer if high rate circulation is required to boost annular velocities. When sheared it will open a circulation path above the DTectR™ Inflow Test Packer