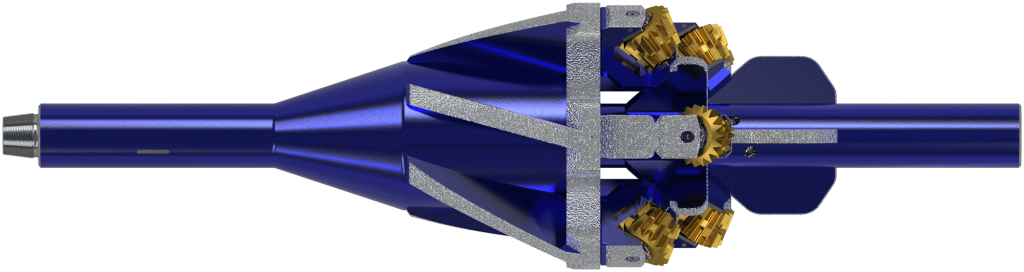

The dual stage design of the Tri-Tornado Hole Opener is a feature which simultaneously increases ROP, cutter lifespan and flow area while allowing the customer to open a hole by two sizes with one hole opener in the string.

The stabilizer blades first centralise the tool in hole, and the initial cutting action is provided by an intermediate diameter stage. The three cutters on the upper stage then complete the boring up to the gauge diameter.

The saddles are machined from a solid billet of steel from an in-house design, bringing durability benefits as well as enabling ease of field service, with all standard security type cutters compatible.

KEY FEATURES

- Body manufactured from a forging for increased WOB

- 6 cutters over 2 stages for maximum performance

- Smooth transition on body and spiral fins for POOH

- Durable, unitised machined saddles

- Excellent hole cleaning capabilities with 6 nozzles

- Hardfacing strategically applied to reduce wear

- Available in various sizes