When strategically placed in the drill string, the Torque Reduction Sub reduces drilling torque and casing wear significantly. It was designed to combat and reduce parasitic torque losses typically found during high angle and horizontal drilling, with the majority of side load (and hence torque loss) occurring during drilling in high angle sections.

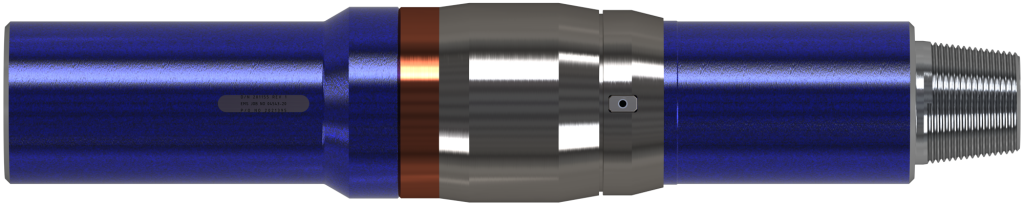

By elevating the tool joints away from the casing or hole wall, the non-rotating outer sleeve ensures the drill pipe rotates freely within the wellbore. This mechanism greatly reduces torque.

The robust, short construction means that the tool performs equally well in both cased and open hole, with a high side load capability. A retaining ring with a patented internal fail-safe mechanism consisting of several keys means the sleeve cannot come off of the mandrel.

A placement program is formulated for each well to optimize the number of torque reduction subs required to achieve a given desired reduction of drill string torque.

KEY FEATURES

- Reduces torque and drag, enhancing drilling efficiency and leading to real time cost savings

- Non-rotating outer sleeve manufactured from casing friendly material, reducing casing wear

- High side load ability of 15,000lbs

- Patented, fail safe sleeve retention system

- Size range from 3-1/2″ to 6-5/8″ based on industry standard drill pipe O/Ds

- Placement program formulated for each well