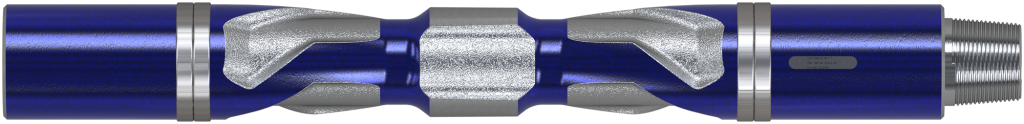

The Hole Cleaning Sub is designed to agitate and re-suspend cuttings which have settled on the low side of the hole, particularly in highly deviated sections in excess of 40° where the build-up of cutting beds is often most acute.

The patented blade profile was designed using computational fluid dynamic techniques where it was originally shown that the tool is able to produce a considerable enhancement in cutting bed dispersal over extended periods of time when compared to a drill string without any mechanical assistance.

The outer impellers first transfer fluid and cuttings towards the centre of the tool, where an impeller works to scoop these cuttings upward into the high velocity zone where mud flow then advects them up the wellbore.

This serves to reduce drill string torque and drag, pick-up and slack-off friction, wiper trips, and stuck pipe issues, especially if run in conjunction with Torque Reduction Tools.

HCS tools are typically located every three stands of drill pipe, however a placement program for optimum hole cleaning can be performed on request.

KEY FEATURES

- Utilises patented impeller and scoop technology, designed to efficiently disperse cutting beds

- Serves to reduce drill string torque and drag, pick-up and slack-off friction, wiper trips and stuck pipe issues

- Short, one-piece, durable tool that can be racked back in the derrick, reducing operational costs and enabling on demand hole cleaning capability

- Hard faced with casing friendly material to reduce casing and tool joint wear, with industry standard hard banding applications available to meet specific customer specifications

- Can be run in conjunction with Torque Reduction Tools

- This product is also available in a Heavy-Weight Drill Pipe format