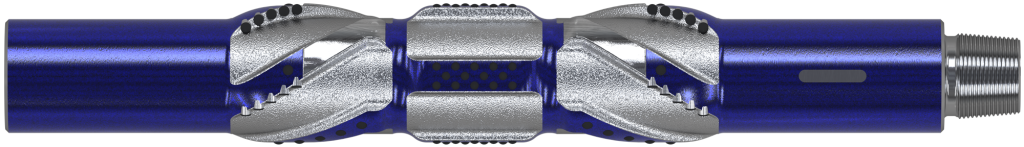

The Eccentric Drilling Reamer creates a smoother and cleaner wellbore with less tight spots in doglegs, leading to improved drill bit durability and a reduction in the number of trips required, as well as reducing potential issues running casing or liners.

The design enables it to slide through the same sections as the drill bit with clearance by bending slightly, yet actively trim the wellbore diameter when the string begins to rotate concentrically.

By slightly enlarging the wellbore and reducing the dog leg severity, the efficiency of drilling is improved while ensuring the BHA will be able to pass through without the need for backreaming.

Should backreaming be required however, the EDR has bidirectional cutting structures, ensuring that the tool is actively performing the same wellbore conditioning and slight enlargement both when drilling ahead but also whenever the string is rotating and travelling uphole.

The patented hole cleaning blade layout is designed to offer not only maximum protection to the cutting structure but also maximum efficiency in creating turbulence to agitate cuttings on the low side of the wellbore in high-angle directional applications, to effect re-suspension.

KEY FEATURES

- Eccentric design effectively allows selective underreaming by only rotating in the desired sections and sliding through others

- No moving parts to wear or fail, no temperature limitations

- Cutting structure is designed to minimise reactive torque by preventing over-engagement. On gauge, single PDC trimmers ensure a well-conditioned hole wall

- Cutter type and structure geometry can be optimized to suit the demands of unique drilling challenges, upon customer request

- Utilises patented impeller and scoop technology, designed to efficiently disperse cutting beds

- One-piece construction ensures a robust tool with maximized tool ID, such as to minimize pressure loss through the tool and allow for fishing of most retrievable MWD components