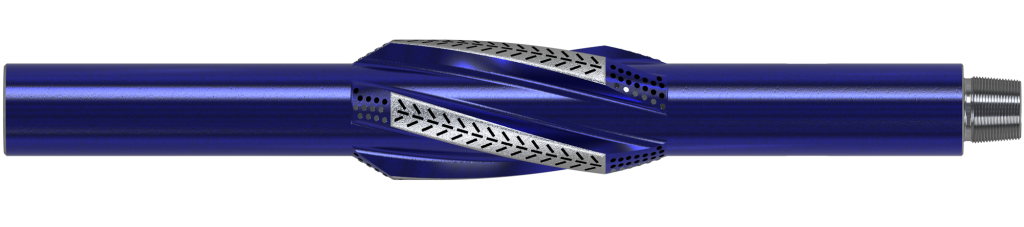

VidDa have a number of Drilling Reamer designs, several of which are bespoke to customer specifications.

The in-house Engineering team have experience of designing drilling reamers in all sizes, and these can be built and dressed to individual requirements. Be it a standard drilling reamer or customized with any cutter type, configuration, blade wrap angle or the optional ability to back ream.

Gauge pad construction can also be altered on request, however the standard hardfacing applied to the blades of drilling reamers is our proprietary VDA-HF001 hardfacing.

For all designs, the cutting structures on the leading edges ream the hole to size, eliminating ledges and delivering a smooth wall to support wellbore integrity in subsequent casing and cementing operations, assisting to make those trouble free.

Wellbore quality is enhanced in swelling shales, clays and difficult salt sections saving backreaming time and subsequent clean up trips to assist in “shoe to shoe” drilling.

KEY FEATURES

- Superior wear resistance and robust cutting structures to maintain gauge in the wellbore

- VDA-HF001 hardfacing, which is used in the most abrasive formations to maximise drilling time as tools stay on gauge, is applied as standard

- No moving parts to wear or fail, no temperature limitations

- Available in all sizes and can be custom built and dressed to individual client requirements

- Continuous reaming operation