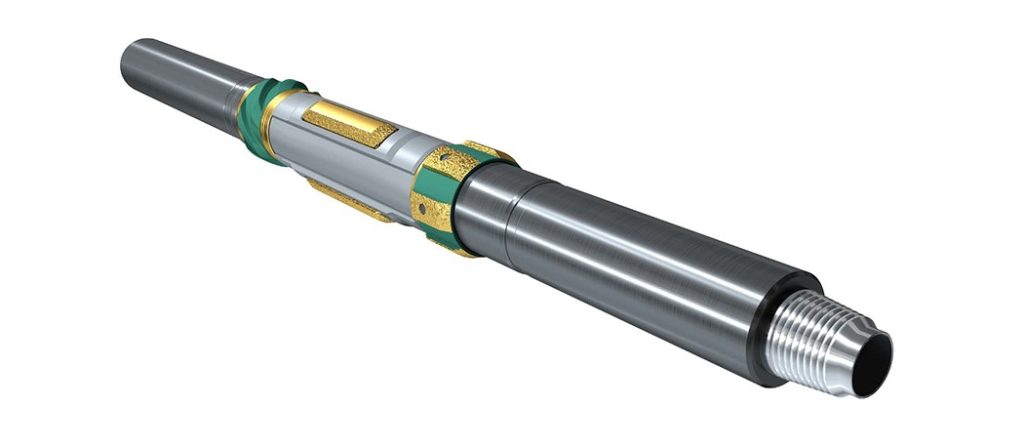

The MillRdillo Deburring Tool™ is a robust milling tool designed to safely mill hard inclusions in the casing inner diameter without causing damage. It can be run individually or modularly as part of the ArmRdillo Wellbore Clean-Up System.

Features

- 3 spring loaded milling blades dressed with tungsten carbide inserts

- The milling elements are fully disengaged from the main tool body to allow the workstring to be rotated without damaging the casing

- Simple and reliable deactivation method using a dropped ball with double shear

- Free-rotating fluted Centralizer Ring provide centralization, bypass and prevents casing wear

Benefits

- Cost Savings

- Allows dressing perforation burrs while performing the wellbore clean-up saving an additional trip in hole

- Increases Well Productivity

- Prevents damage to zonal isolation packers and production screens when running in hole

- Integrity

- Can be provided with any type of rig end connections including premium and high torque connections reducing the need for reduced strength crossovers

- Reducing NPT

- Mitigates premature lower completion failure

- Mitigates premature lower completion failure

Applications

- Features spring loaded milling blades which can be disengaged when required

- Designed to remove perforation burrs, milled out float equipment and other items which may not be removed normally by casing scrapers

- Pre-completion wellbore clean-up operations where there is a requirement to remove perforation burrs such as

- Cased hole gravel packs

- Multi-stage fracs

- Zonal isolation

- Cleaning drilled out shoe tracks or cement equipment

Operational

- While running in hole, the milling element of the MillRdillo™ are locked rotationally to the tool body and can be rotated with the rest of the workstring

- Run in hole to the area of interest and ream the MillRdillo™ over the interval several times to remove any imperfections on the casing/liner wall

- Once the milling operation is complete drop the activation ball to disengage the milling blades

- The milling blades will no longer rotate with the workstring and the well can be cleaned up and displaced while rotating and recriproating the string without damaging the casing